Hydraulic pumps are essential components in various machinery and equipment, enabling them to perform powerful tasks with precision and ease. These pumps convert mechanical energy and motion into hydraulic fluid power, and their efficiency and type can significantly impact the performance of a hydraulic system. In this guide, we’ll delve into the different types of hydraulic pumps, their functions, and applications, providing you with a clear understanding of which pump might be best suited for your needs.

What is a Hydraulic Pump?

Imagine trying to lift a heavy stone with your hands—it’s tough. But if you use a tool that can push oil through a small tube under high pressure, you can use that pressure to move the stone easily. That’s what a hydraulic pump does, it moves oil or another fluid with enough force to do heavy jobs without a sweat.

Types of Hydraulic Pumps

There are several different types of hydraulic pumps, and each has its special job:

-

Gear Pumps

These are simple and common pumps that use gears to move the hydraulic fluid. Picture two gears in a box that fit into each other perfectly. When these gears spin, they push the fluid from one side of the pump to the other. Gear pumps are tough and can last a long time, making them perfect for many jobs.

-

Vane Pumps

Vane pumps have a spinning wheel inside with many sliding pieces called vanes. These veins stick out and pull in as they spin around, scooping up fluid and pushing it along. These pumps are great for jobs that need a steady flow of fluid at a constant pressure.

-

Piston Pumps

These pumps use small cylinders (pistons) that move back and forth. The moving pistons suck in and push out the fluid, creating high pressure. Piston pumps are very strong and are used for jobs that need a lot of force, like in hydraulic presses or heavy lifting equipment.

-

Screw Pumps

Imagine a giant screw inside a tube. As the screw turns, it moves the fluid along the threads from one end to the other. Screw pumps are good at handling thick fluids and are used in places like oil refineries and chemical plants.

-

Peristaltic Pumps

These are different from the others. They work by squeezing a tube or hose with rollers or shoes. The squeezed part moves along the tube, pushing the fluid in front of it. These pumps are excellent for moving clean or sensitive fluids because the fluid only touches the tube and nothing else.

Choosing the Right Pump

Choosing the right hydraulic pump depends on what you need it for. Gear pumps are good for general tasks, vane pumps are great for steady jobs, piston pumps offer power for tough tasks, screw pumps handle thick fluids well, and peristaltic pumps are best for clean or sensitive fluids.

Related: Hydraulic Repair Experts Near British Columbia Canada

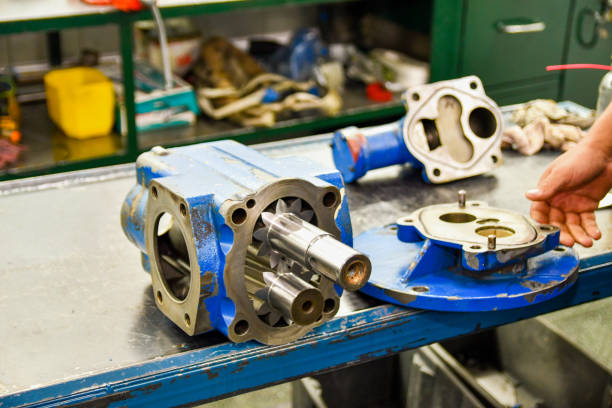

Hydraulic Pump Repair

Even the toughest pumps need a little TLC. If your pump starts making strange noises, loses power, or starts leaking, it might be time for a repair. Regular checks can help avoid big problems later. And if you’re in Chilliwack, BC, Delanges Industries specializes in keeping your hydraulic pumps running smoothly.

Maintenance Tips

-

Regularly check fluid levels and quality. Contaminated or low fluid can lead to pump failure.

-

Inspect the pump and associated components for signs of wear or damage.

-

Ensure that the hydraulic system is not being overloaded by operating within the recommended pressure ranges.

Delanges Industries LTD Has You Covered

At Delanges Industries LTD, we know hydraulic pumps inside and out. Whether you need a new pump or repair services in Chilliwack, BC, we’re here to help. Our team of experts ensures that your hydraulic systems work flawlessly and efficiently, minimizing downtime and maximizing productivity.

Ready to get the best in hydraulic pump repair? Contact Delanges Industries LTD today and ensure your equipment is in top shape! Call us or visit our service center for all your hydraulic needs.

This guide helps you understand different hydraulic pumps in simple terms, making it easier to choose the right one for your needs. Remember, a well-maintained hydraulic system is key to efficient and reliable machinery.

Related: Expert Hydraulic Repair Services in British Columbia: Ensuring Efficiency and Reliability