Exploring the Innovation Behind Weavetech Fancy Yarn Machines

In the ever-evolving textile industry, the demand for unique and high-quality fabrics has led to significant advancements in yarn manufacturing. Weavetech, a leading textile machinery manufacturer based in Surat, India, has been at the forefront of this innovation. Their range of fancy yarn machines exemplifies the fusion of technology and creativity, enabling manufacturers to produce distinctive yarns that meet the diverse needs of modern textiles.

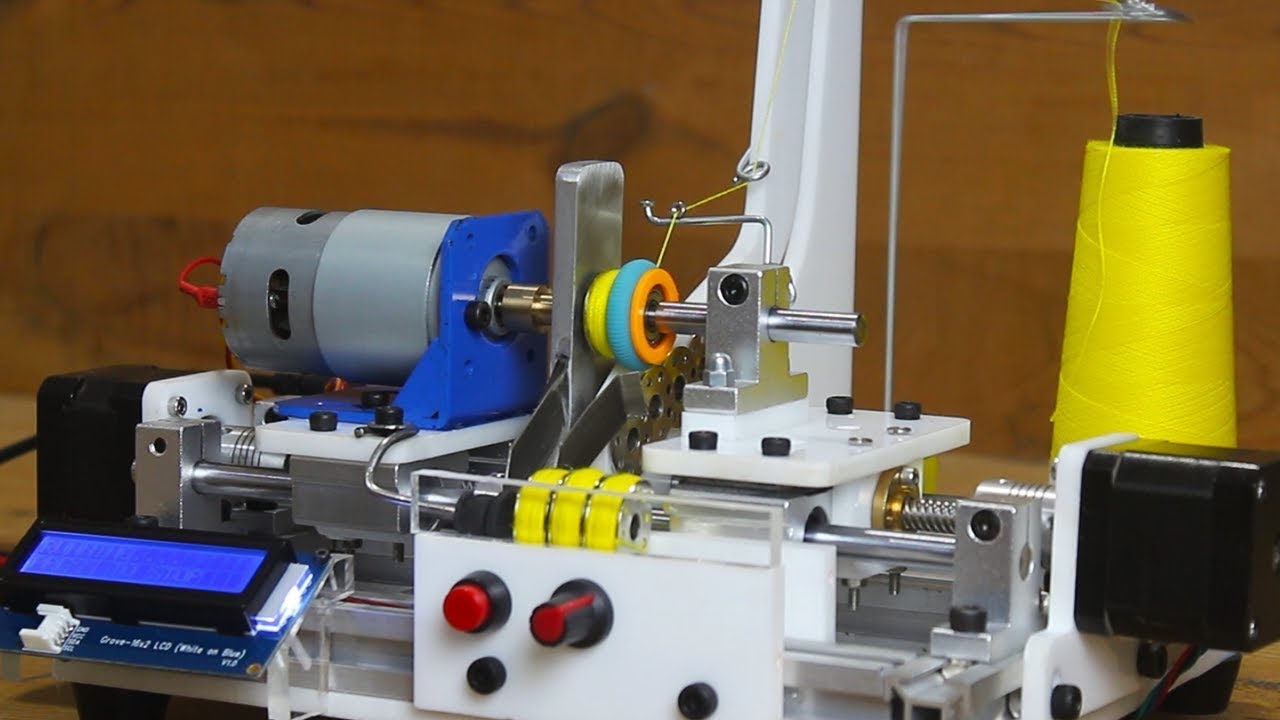

Understanding Fancy Yarn Machines

Fancy yarn machines are specialized equipment designed to create textured and decorative yarns. These machines allow for the production of yarns with varying thicknesses, twists, and patterns, adding aesthetic value to fabrics. By integrating multiple yarns, colors, and textures, fancy yarn machines enable the creation of fabrics with enhanced visual appeal and tactile qualities.

Weavetech’s Commitment to Innovation

Weavetech’s dedication to innovation is evident in their extensive range of fancy yarn machines. Each machine is engineered to meet specific market requirements, ensuring versatility and efficiency in yarn production. The company’s focus on research and development has led to the introduction of several advanced features in their machines, setting new standards in the industry.

Key Features of Weavetech’s Fancy Yarn Machines

1. FT-Series: Versatility in Yarn Production

The FT-Series machines are designed for producing multi-ply and multi-color yarns, offering flexibility in creating various yarn effects. With programmable drafting and covering options, these machines allow for the customization of yarn characteristics to suit different fabric requirements. The FT-Series is ideal for applications in garments and upholstery, where unique yarn designs are essential.

2. STR-Series: High Shrinkage Yarns for Specialized Applications

The STR-Series machines cater to the production of high shrinkage yarns, suitable for label weaving and knitting segments. These machines incorporate heat-setting and stabilizing processes, resulting in soft, voluminous yarns with stretch effects. The STR-Series is particularly beneficial for applications requiring continuous heat-setting of twisted yarns.

3. ACW-Series: Air Covering Winder for Multi-Ply Yarns

The ACW-Series machines are equipped with intermingling jets, enabling the production of multi-ply filament yarns. These machines are designed to combine multiple yarns, including elastane, ensuring smooth processing in weaving. The ACW-Series is suitable for garment fabric producers looking to introduce elasticity in combination with a wide range of yarns.

4. HC-Series: Hollow Covering for Enhanced Yarn Properties

The HC-Series machines focus on hollow covering techniques, enhancing the bulk and softness of yarns. By incorporating hollow structures, these machines produce yarns with improved insulation properties, making them ideal for applications in upholstery and home textiles.

5. CD-Series: Compact Design for Efficient Yarn Production

The CD-Series machines feature a compact design, saving space while maintaining high production efficiency. These machines are suitable for producing a variety of fancy yarns, offering flexibility and ease of operation.

Advantages of Weavetech’s Fancy Yarn Machines

-

Customization: Weavetech’s machines offer programmable settings, allowing manufacturers to customize yarn characteristics to meet specific fabric requirements.

-

Efficiency: The advanced technology integrated into these machines ensures high-speed production with minimal downtime, enhancing overall efficiency.

-

Quality: Weavetech’s commitment to quality is reflected in the precision and consistency of the yarns produced, meeting international standards.

-

Sustainability: The machines are designed to minimize energy consumption and reduce waste, contributing to sustainable manufacturing practices.

Applications in the Textile Industry

Weavetech’s fancy yarn machines cater to various segments of the textile industry, including:

-

Apparel Manufacturing: Producing unique yarns for fashion fabrics, enhancing the aesthetic appeal of garments.

-

Home Textiles: Creating yarns with improved insulation properties for upholstery and home furnishings.

-

Technical Textiles: Manufacturing specialized yarns for applications requiring specific performance characteristics.

Conclusion

Weavetech’s innovative fancy yarn machines play a pivotal role in transforming the textile industry. By integrating advanced technology and design, these machines enable manufacturers to produce distinctive yarns that meet the diverse needs of modern textiles. As the industry continues to evolve, Weavetech remains committed to providing solutions that drive innovation and excellence in yarn production.

Explore Weavetech’s range of fancy yarn machines and discover how our innovative solutions can enhance your textile production. Visit Weavetech’s Fancy Yarn Machines to learn more and request a quote.