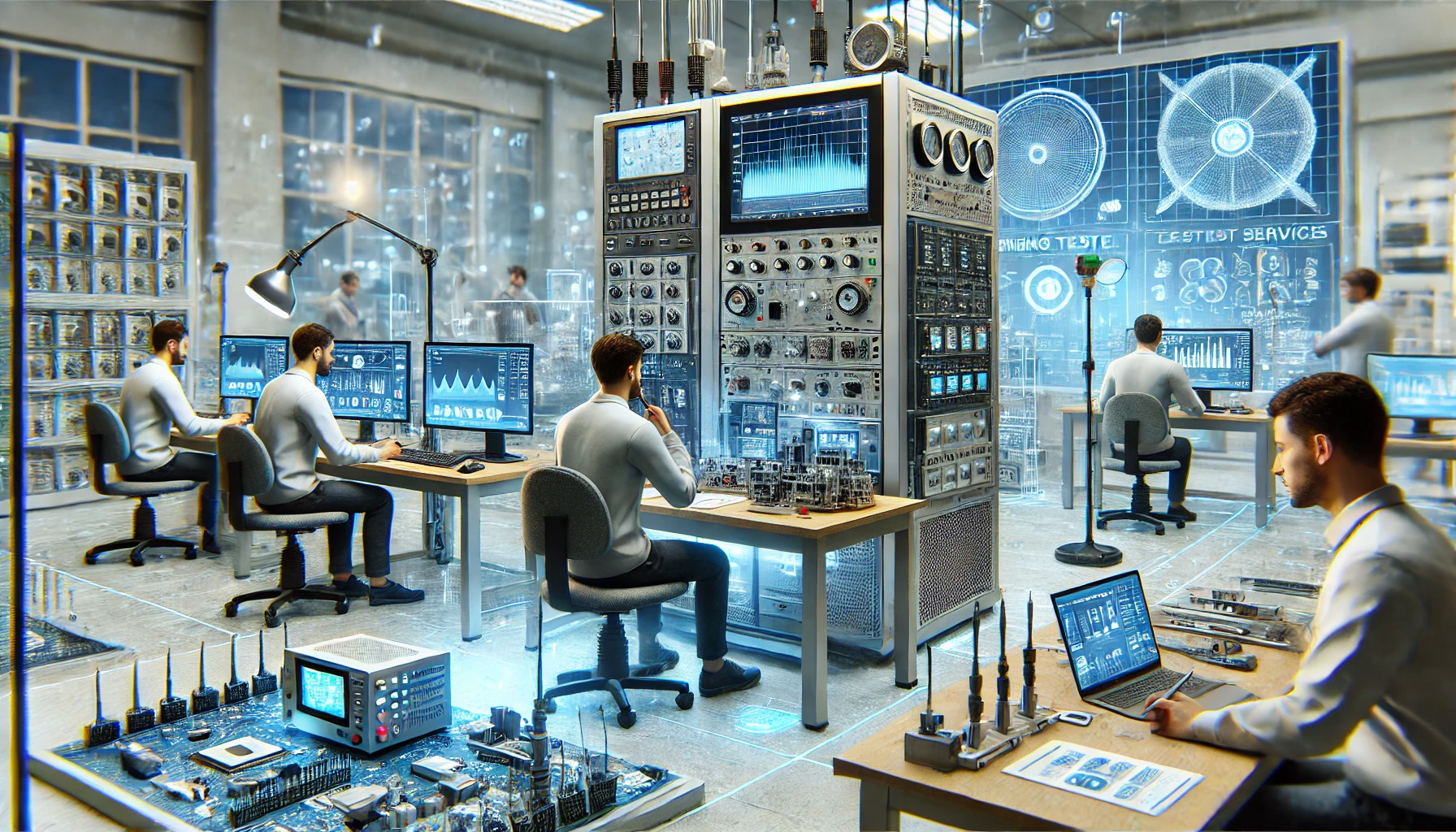

In today’s rapidly evolving industrial landscape, precision, reliability, and efficiency are crucial in product development. Engineering test services play a vital role in ensuring that products meet high-quality standards, perform optimally, and comply with industry regulations. These services help businesses minimize failures, reduce costs, and accelerate time to market, making them essential for industries such as electronics, telecommunications, automotive, and aerospace.

Understanding Engineering Test Services

Engineering test services encompass a wide range of testing methodologies used to evaluate and validate the functionality, durability, and efficiency of a product or system. From prototype testing to final product validation, these services ensure that every component meets design specifications and regulatory requirements.

With advancements in automation and technology, modern engineering test services are more sophisticated, integrating real-time monitoring, AI-driven analysis, and precision instruments to enhance accuracy and reliability.

Key Benefits of Engineering Test Services

1. Improved Product Quality and Reliability

One of the most significant advantages of engineering test services is their ability to detect defects and inconsistencies early in the development cycle. Through rigorous testing procedures, companies can ensure their products function as intended, reducing the risk of malfunctions and enhancing customer satisfaction.

2. Cost Reduction and Efficient Resource Utilization

Identifying issues early prevents costly redesigns and production delays. By investing in engineering test services, businesses can reduce wastage, optimize material usage, and avoid expensive recalls, ultimately leading to more efficient resource utilization.

3. Faster Time to Market

In competitive industries, speed is crucial. Engineering test services streamline the validation process, enabling businesses to refine and launch their products faster without compromising quality. Automated testing further accelerates this process by providing instant feedback and data-driven insights.

4. Compliance with Industry Standards

Modern industries must adhere to strict regulatory and safety standards. Engineering test services help businesses comply with these requirements by conducting thorough evaluations based on industry-specific guidelines. This reduces the risk of legal issues and ensures product safety and reliability.

5. Enhanced Performance with Manufacturing Test Systems

For industries relying on mass production, manufacturing test systems are integral to maintaining consistency and efficiency. These systems automate testing processes, ensuring every unit produced meets predefined quality benchmarks. By integrating manufacturing test systems into production lines, companies can achieve higher accuracy, reduce human error, and enhance operational efficiency.

Applications of Engineering Test Services in Modern Industries

- Electronics & Telecommunications: Ensuring device performance, signal integrity, and compliance with RF standards.

- Automotive & Aerospace: Testing components for durability, thermal resistance, and mechanical stress.

- Medical Devices: Verifying product safety, precision, and regulatory compliance.

- Energy & Industrial Equipment: Assessing efficiency, reliability, and operational safety.

Final Thoughts

As industries continue to push the boundaries of innovation, the demand for high-quality testing solutions grows. Companies that leverage engineering test services and integrate advanced manufacturing test systems into their processes can achieve superior product reliability, cost efficiency, and faster market readiness.

For businesses looking to optimize their testing capabilities, Orbis Systems provides advanced and customized solutions. With expertise in RF testing, automation, and precision engineering, Orbis Systems ensures top-tier product validation, helping industries achieve excellence in their testing processes.