Introduction

Precast detailing is revolutionizing modern construction by ensuring precise planning, faster execution, and cost-effective project management. As the construction industry moves toward more efficient and sustainable practices, mastering precast detailing has become essential for engineers, architects, and builders.

In this comprehensive guide, we’ll dive deep into:

- The fundamentals of precast detailing

- Why it’s crucial for efficient construction

- Key components and software used

- The latest industry trends shaping the future

Let’s explore how precast detailing can transform construction efficiency and quality in 2025 and beyond.

What is Precast Detailing?

Precast detailing is the process of designing and detailing precast concrete elements before they are manufactured. This involves creating accurate shop drawings, reinforcement details, and connection plans to ensure a seamless assembly on-site.

Think of precast detailing like assembling a complex puzzle—every element must be perfectly designed to fit together without any errors. When done correctly, it prevents delays, reduces costs, and improves structural integrity.

Why is Precast Detailing Critical in Modern Construction?

1. Faster Project Completion

Unlike traditional on-site concrete pouring, precast elements are manufactured in a factory, allowing simultaneous site preparation and component production. This parallel workflow significantly speeds up construction timelines.

2. Precision & Quality Control

Precast elements are produced in a controlled environment with strict quality measures. This eliminates errors caused by weather conditions, human mistakes, and on-site inconsistencies.

3. Cost-Efficiency & Waste Reduction

With accurate detailing, material usage is optimized, minimizing waste and reducing costs. Precast detailing ensures the right amount of concrete, reinforcement, and connections are used efficiently.

4. Enhanced Safety

Factory-made precast elements have fewer defects and higher strength than on-site poured concrete, reducing safety risks for workers and occupants.

5. Sustainability & Eco-Friendliness

Precast detailing supports sustainable construction by reducing on-site material waste, optimizing resource utilization, and promoting energy-efficient building practices.

Where is Precast Concrete Used?

Precast concrete is widely used across various industries due to its strength, durability, and efficiency:

- Commercial Buildings – Shopping malls, office buildings, and warehouses.

- Residential Projects – Apartment complexes, villas, and housing developments.

- Infrastructure – Bridges, metro stations, tunnels, and highways.

- Industrial Structures – Factories, storage facilities, and parking garages.

Key Components of Precast Concrete Structures

Each precast element serves a specific function in construction:

- Precast Slabs – Used for floors and ceilings (hollow-core, solid, or double-tee slabs).

- Precast Columns & Beams – Provide structural support.

- Precast Walls – Load-bearing and non-load-bearing walls.

- Precast Stairs & Landings – Essential for staircases in buildings.

These components are manufactured off-site, transported, and assembled at the construction site like a modular system.

Precast vs. Traditional Cast-in-Place Concrete

| Feature | Precast Concrete | Cast-in-Place Concrete |

|---|---|---|

| Speed | Faster production & installation | Takes longer due to on-site pouring |

| Quality Control | Factory-made with strict QC | Prone to weather & human errors |

| Cost Efficiency | Less material waste & labor costs | Higher costs due to manual on-site work |

| Durability | Stronger due to controlled curing | May have inconsistencies |

Precast Detailing Process: Step-by-Step

1. Understanding Project Requirements

Engineers and architects collaborate to determine the project’s design, load-bearing requirements, and functional needs.

2. Creating 3D BIM Models

Using Building Information Modeling (BIM) software, engineers create 3D models to visualize structural elements and detect potential issues early.

3. Generating Shop Drawings

Precise technical drawings are created to guide manufacturing, ensuring accuracy in measurements, reinforcement, and connections.

4. Adding Reinforcement Details

Steel reinforcements are detailed to enhance structural strength, preventing cracks and failures.

5. Quality Check & Approval

All details are reviewed before manufacturing begins to eliminate errors and prevent costly rework.

Best Software for Precast Detailing

| Software | Features |

| Tekla Structures | BIM-based detailing, clash detection, automated shop drawings |

| AutoCAD | 2D & 3D drafting for precast detailing |

| Revit | Advanced parametric modeling for precast elements |

| StruCAD, Allplan, BricsCAD | Other specialized precast detailing tools |

Using these software solutions ensures precise modeling, accurate documentation, and seamless collaboration in precast projects.

Challenges in Precast Detailing & Solutions

| Challenge | Solution |

| Dimensional Errors | Utilize 3D modeling software to catch mistakes early. |

| Complex Connection Designs | Standardize joint designs for simpler assembly. |

| Transportation & Handling Issues | Optimize element sizes for easy transport. |

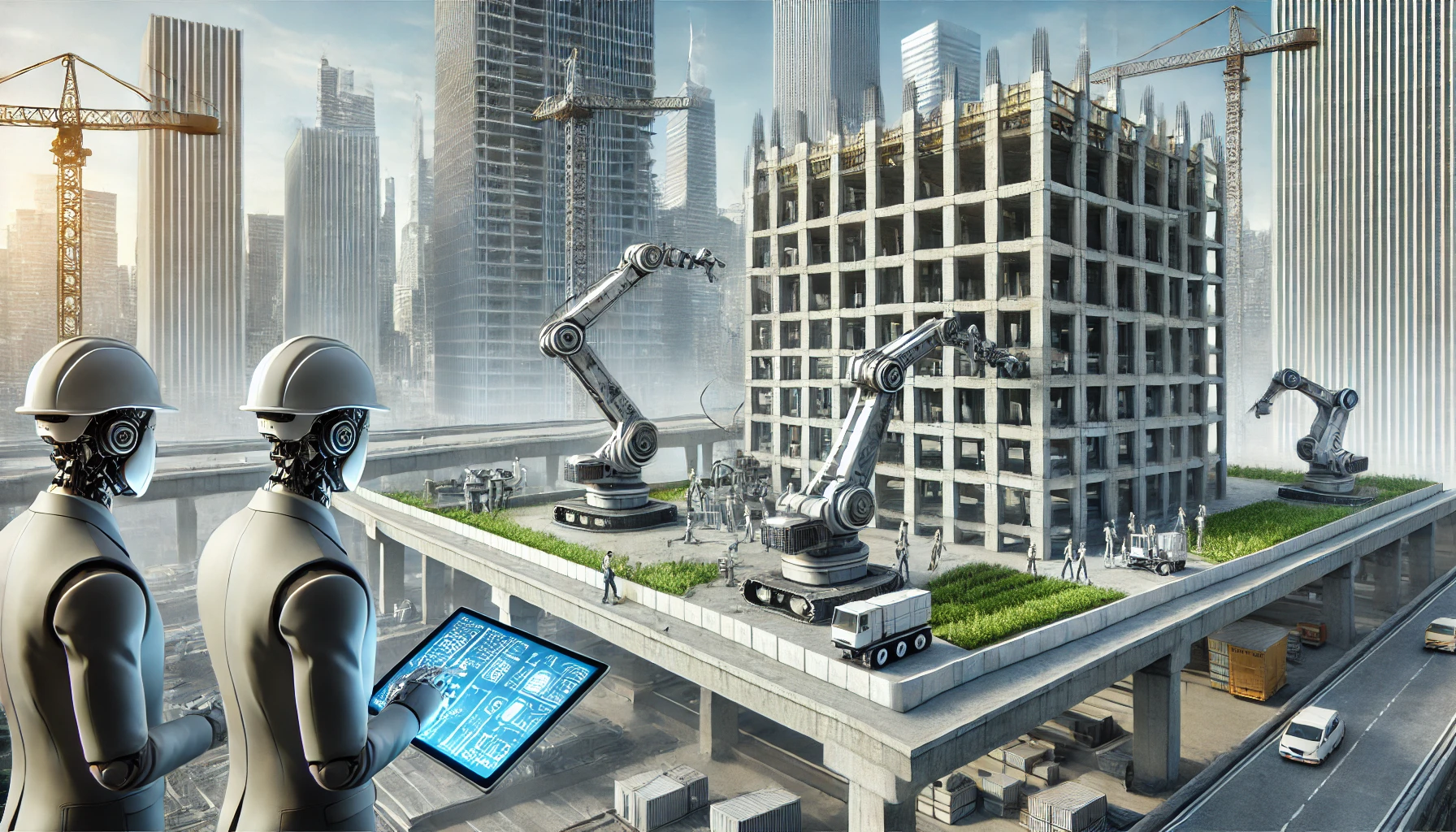

Future Trends in Precast Detailing

✅ Automation & AI – AI-powered detailing tools for faster, error-free designs. ✅ 3D Printing – Printing precast elements for rapid, sustainable production. ✅ Digital Twins – Real-time monitoring and predictive maintenance for precast structures. ✅ Green Precast Materials – Eco-friendly, low-carbon concrete solutions.

With advancements in AI, digital construction, and automation, precast detailing is becoming more efficient, precise, and sustainable than ever before.

Final Thoughts

Precast detailing is reshaping modern construction by enhancing efficiency, reducing costs, and improving structural integrity. By leveraging cutting-edge software, adhering to industry standards, and embracing emerging trends, professionals can deliver high-quality precast projects with minimal errors and maximum efficiency.

For expert assistance, explore our precast detailing services to ensure accuracy and excellence in your next project.