In today’s technology-driven world, power electronics testing plays a crucial role in ensuring the reliability, efficiency, and performance of various electronic systems. From industrial applications to consumer electronics and automotive innovations, power electronics are the backbone of modern electrical systems. As these components become more complex and integrated into mission-critical applications, thorough testing is necessary to maintain high-quality standards and prevent failures.

This article explores the importance of power electronics testing, the role of test equipment design, and how automotive test solutions contribute to the development of robust and efficient electronic systems.

The Importance of Power Electronics Testing

Power electronics are used in a variety of applications, including power supplies, electric vehicles, renewable energy systems, and industrial automation. Given their critical functions, even minor failures can result in performance issues, reduced efficiency, or complete system breakdowns. This makes power electronics testing an essential process in the manufacturing and development cycle.

Ensuring Performance and Efficiency

Testing helps validate that power electronic components, such as inverters, converters, and power management systems, operate efficiently under different conditions. By simulating real-world scenarios, manufacturers can identify weaknesses and optimize designs to ensure maximum efficiency and performance.

Detecting and Preventing Failures

A single faulty power component can compromise an entire system, leading to costly repairs and downtime. Comprehensive power electronics testing helps detect early-stage failures, ensuring that only high-quality products reach the market. Reliability testing also verifies that components can withstand harsh operating conditions, including temperature variations, electrical stress, and long-term wear.

Compliance with Industry Standards

To ensure safety and reliability, power electronic devices must comply with industry regulations and certification requirements. Testing verifies that products meet standards such as IEC, IEEE, and automotive-specific requirements, ensuring they can be safely used in real-world applications.

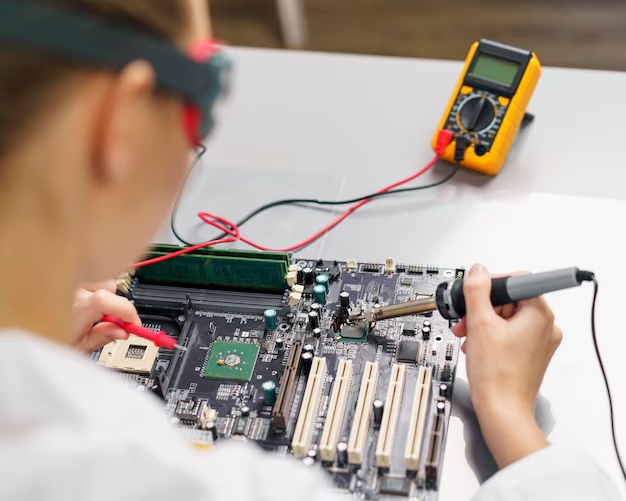

The Role of Test Equipment Design in Power Electronics Testing

To achieve accurate and reliable test results, the design of test equipment plays a crucial role. Well-designed testing systems ensure that power electronics undergo rigorous evaluations under controlled conditions.

Key Considerations in Test Equipment Design

- Accuracy and Precision – High-precision measurement instruments are essential for capturing detailed data about voltage, current, and power efficiency.

- Scalability and Flexibility – Test equipment should support a range of power levels and be adaptable to different types of devices and applications.

- Automation and Data Analysis – Modern test setups include automated test sequences and advanced data analytics to enhance efficiency and reduce human error.

- Safety Features – High-voltage and high-current testing environments require built-in safety measures to protect both equipment and personnel.

Innovative test equipment design integrates smart features such as AI-based diagnostics and cloud connectivity to enhance testing capabilities. As power electronics become more advanced, testing solutions must evolve to keep pace with new technologies.

Automotive Test Solutions: Power Electronics in Vehicles

The automotive industry relies heavily on power electronics, especially with the rise of electric vehicles (EVs) and hybrid systems. From battery management systems (BMS) to motor controllers, automotive test solutions ensure that every component meets stringent performance and safety standards.

Challenges in Automotive Power Electronics Testing

- High Voltage and High Current Testing – EV powertrains operate at high voltages, requiring specialized test solutions to ensure safe and accurate measurements.

- Thermal Management – Power electronics generate heat, and effective testing must assess how well components handle thermal stress.

- EMC and EMI Compliance – Ensuring that electronic systems do not interfere with vehicle communication and control networks is a major challenge in automotive electronics testing.

- Battery Performance and Safety – Battery testing includes charge-discharge cycles, aging analysis, and fault detection to ensure long-term reliability.

Advanced Automotive Test Solutions

Leading automotive test solutions include:

- Dynamometer Testing – Evaluates the efficiency and performance of electric motors and powertrain components.

- Hardware-in-the-Loop (HIL) Testing – Simulates real-world driving conditions to test power electronic systems in a controlled environment.

- Battery Testing Systems – Assess battery life, efficiency, and safety under different load conditions.

- End-of-Line Testing – Ensures that every manufactured power electronic component meets quality standards before deployment.

The Future of Power Electronics Testing

As power electronics continue to evolve, testing methodologies must also advance to keep up with industry demands. Emerging trends include:

- AI-Powered Testing – Machine learning algorithms can predict failures and optimize test procedures.

- IoT-Connected Test Systems – Cloud-based monitoring allows real-time performance tracking and remote diagnostics.

- Simulation-Based Testing – Digital twin technology enables virtual testing before physical prototypes are built.

By integrating these technologies, power electronics testing will become even more efficient, ensuring that products meet the highest standards of reliability and performance.

Conclusion

Power electronics are at the heart of modern technological advancements, and their reliability is non-negotiable. Through rigorous power electronics testing, manufacturers can enhance performance, prevent failures, and comply with industry standards. A well-designed test equipment design ensures accuracy, scalability, and automation in the testing process. Meanwhile, automotive test solutions are crucial in developing safe and efficient power electronics for electric and hybrid vehicles.

As the industry continues to evolve, adopting advanced testing methodologies will be key to ensuring high-quality, energy-efficient, and reliable power electronics solutions.