Overview

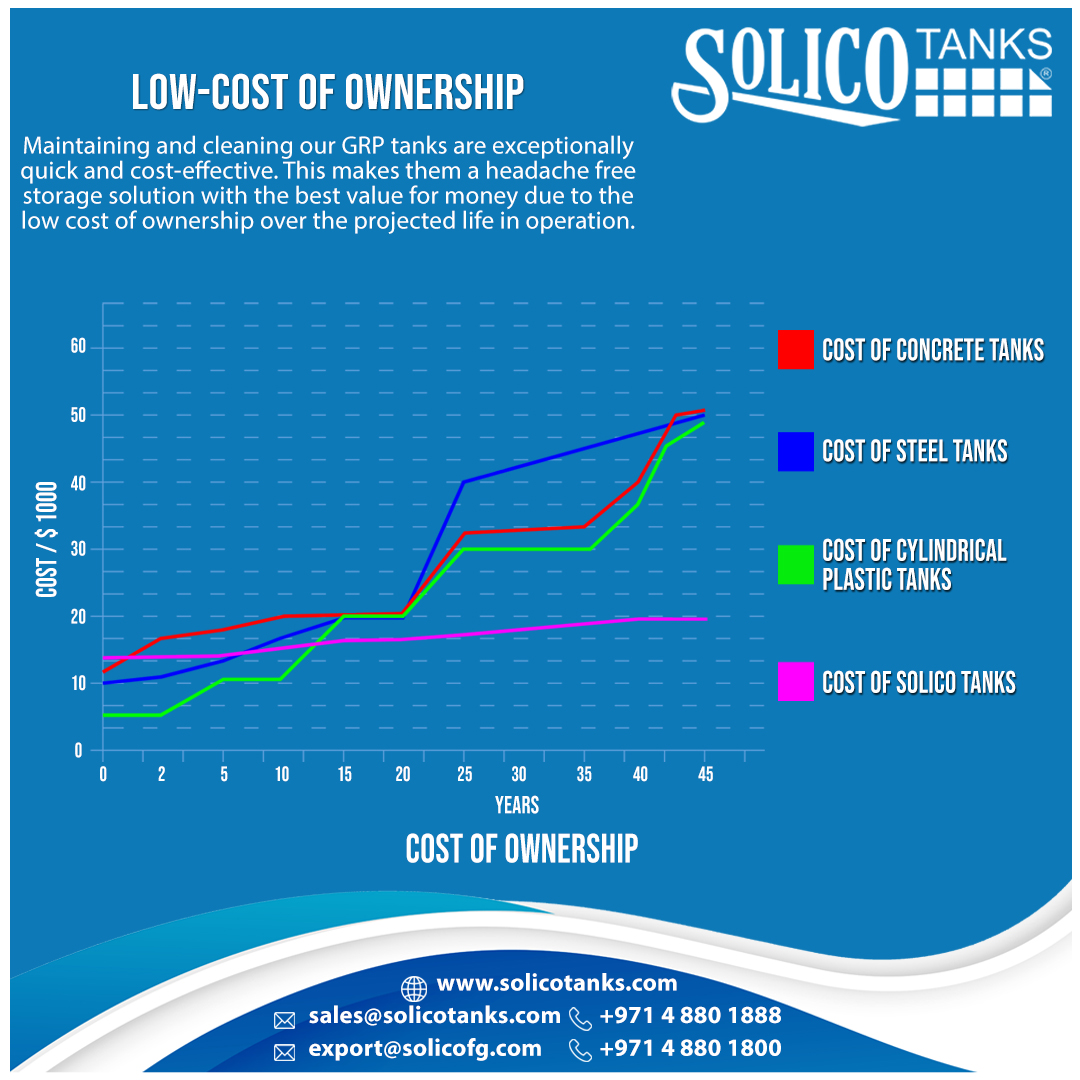

When evaluating water storage solutions, GRP panel tanks present a compelling case for long-term cost-effectiveness compared to traditional materials like steel, concrete, and plastic. While GRP tanks may involve higher initial costs, their modular design and lightweight structure lead to reduced transportation and installation expenses, minimizing site preparation and shortening project timelines. This results in significant savings over time, as fewer labor hours and lower costs are required for assembly.

GRP tanks also provide considerable benefits in terms of durability, with features such as corrosion resistance, UV stabilization, and the ability to withstand extreme temperatures, contributing to a lifespan of over 50 years. This long service life, coupled with minimal maintenance needs, allows GRP tanks to significantly reduce long-term operational and repair expenses, making them a more economical option in the long run.

In contrast, while traditional materials like steel and concrete may offer lower upfront costs, they often come with higher maintenance and operational expenses. Steel tanks, for example, require regular maintenance to prevent corrosion and extend their lifespan, while concrete tanks can be subject to cracking and require costly repairs. Plastic tanks may have the lowest initial cost, but their limited durability and vulnerability to UV degradation can lead to shorter lifespans and more frequent replacements.

GRP panel tanks, with their low maintenance and extended lifespan, offer a clear advantage, especially when considering the total cost of ownership. Their environmental benefits, such as recyclability and energy-efficient production, further enhance their value, making them a sustainable and cost-effective choice for water storage in both residential and industrial applications.

What Are GRP Panel Water Tanks?

GRP (Glass Reinforced Plastic) panel water tanks are advanced water storage solutions made by combining fiberglass with resin, creating a material known for its strength, durability, and versatility. These tanks offer significant advantages over traditional materials such as steel, concrete, and plastic.

A key feature of GRP tanks is their modular design, which enables easy transportation, installation, and scalability. This makes them ideal for projects of varying sizes, from small residential systems to large-scale industrial and municipal applications. GRP panel tanks are available in customizable shapes and sizes, allowing them to fit specific space requirements and adapting to different environments. Their lightweight construction further simplifies installation and reduces the need for heavy machinery, resulting in cost savings on transportation and labor.

The exceptional durability of GRP tanks is another major advantage. Their corrosion resistance ensures a long lifespan, making them ideal for use in harsh environments, including coastal areas where traditional steel tanks may rust or degrade. GRP tanks are also UV resistant, preventing material breakdown from sun exposure, which helps maintain their integrity and appearance over time.

Additionally, the smooth, non-porous surface of GRP tanks minimizes the growth of algae and bacteria, promoting better water quality and reducing maintenance needs. This translates to lower ongoing operational costs compared to traditional tanks that require frequent repairs, repainting, or replacements. Furthermore, GRP tanks require minimal maintenance due to their resilience, reducing both long-term upkeep and water treatment costs. The combination of strength, versatility, low maintenance, and longevity makes GRP panel water tanks a highly cost-effective and sustainable alternative to conventional water storage materials.

Initial Costs: GRP vs. Traditional Materials

When comparing the initial costs of GRP (Glass Reinforced Plastic) panel water tanks to traditional materials, there are several important factors to consider.

GRP Tanks typically have a higher upfront cost than some traditional options, but they offer several financial advantages that make them a cost-effective choice in the long run. The modular nature of GRP tanks allows for reduced transportation expenses because the panels are lightweight and easy to handle. Additionally, GRP tanks are quicker to install, reducing labor costs and project timelines. They also require minimal site preparation, further lowering initial setup costs. These factors can offset the higher upfront price, making GRP tanks a smart investment over time.

Steel Tanks, while having a lower initial purchase cost, come with additional ongoing expenses. Due to their weight, steel tanks incur higher transportation costs. Installation can be more time-consuming, requiring extensive site preparation, which increases labor costs. Moreover, steel tanks are prone to corrosion, necessitating regular maintenance, such as protective coatings and repainting, to maintain their structural integrity and prevent rust, especially in harsh environments. These maintenance costs can accumulate over time, making steel tanks more expensive in the long run.

Plastic Tanks generally come with the lowest initial costs due to the affordability of materials. They are lightweight and easy to transport, making installation straightforward and inexpensive. However, plastic tanks are vulnerable to UV degradation, which can cause them to become brittle and degrade over time. This limits their lifespan and could lead to early replacement costs. In areas with high UV exposure, this could be a significant drawback compared to GRP or steel tanks.

Concrete Tanks represent the highest initial investment due to the complex construction process and the need for extensive site preparation. Concrete tanks require heavy equipment for installation, and the construction process is time-consuming, which increases labor costs. Additionally, concrete tanks are prone to cracking over time, especially in areas with shifting ground, and repairs can be costly and challenging. The high initial costs and ongoing maintenance make concrete tanks a less economical option for many projects.

Overall, while GRP tanks may have a higher initial cost than some other materials, their long-term cost-effectiveness is enhanced by reduced transportation, installation, and maintenance costs, making them a favorable choice in many water storage applications.

Durability and Lifespan

GRP (Glass Reinforced Plastic) tanks are known for their exceptional durability, with a lifespan that can exceed 50 years when properly maintained. These tanks are highly resistant to corrosion, UV damage, and extreme temperatures, making them ideal for use in a wide range of environments. This long lifespan contributes to their overall cost-effectiveness, as they require minimal maintenance over time and can continue performing reliably for decades.

In comparison, Steel Tanks typically last between 5 to 10 years, but their relatively short lifespan requires regular maintenance to prevent rust and corrosion. This ongoing upkeep can significantly increase costs over time. Plastic Tanks, while affordable upfront, degrade quickly, often within 2 to 3 years, particularly under UV exposure, limiting their overall lifespan and effectiveness. Concrete Tanks generally last around a decade, but they are prone to cracking, especially in areas with shifting ground or extreme weather conditions. These cracks can lead to expensive repairs, further diminishing their cost-effectiveness in the long run. Thus, GRP tanks offer a superior durability and lifespan advantage, requiring less maintenance and fewer replacements over time.

Maintenance and Operational Costs

GRP tanks are known for their minimal maintenance requirements, which leads to significant savings in cleaning and repair costs. Their smooth, non-porous surface resists the growth of algae and bacteria, reducing the need for frequent cleaning. Additionally, they do not require coatings or regular inspections, making them cost-effective to maintain over time.

In contrast, Steel Tanks require regular inspections to detect rust and ensure structural integrity. They also need protective coatings applied periodically, which can add to maintenance expenses. Plastic Tanks, while low-maintenance compared to steel, still require routine cleaning and inspections for UV damage, as prolonged exposure can cause brittleness. Concrete Tanks are the most maintenance-intensive, needing frequent repairs due to cracks and waterproofing treatments to prevent leaks. These ongoing maintenance needs can significantly increase the total operational costs of steel, plastic, and concrete tanks, whereas GRP tanks offer a more cost-efficient and hassle-free alternative.

Water Quality and Treatment

GRP tanks excel in maintaining high water quality due to their non-porous surface, which prevents bacterial growth and eliminates the risk of chemical leaching. This ensures that water stored in GRP tanks requires less treatment, ultimately reducing operational costs. Additionally, the smooth interior minimizes sediment buildup, helping to preserve the water’s purity.

On the other hand, Steel Tanks can introduce rust and other contaminants into the water, requiring more frequent treatment and potentially impacting water quality. Plastic Tanks, especially those with translucent designs, are prone to algae growth, which can compromise water quality and necessitate additional cleaning. Concrete Tanks can leach minerals, such as lime, into the water, which can alter its quality. These issues lead to higher treatment costs and potential contamination risks, making GRP tanks a superior choice for maintaining clean, safe water with minimal ongoing treatments.

Environmental Impact

GRP tanks are an environmentally friendly option, as they are fully recyclable and manufactured using energy-efficient processes. Their lightweight design not only reduces transportation emissions but also contributes to lower energy consumption during production and delivery. The overall environmental footprint of GRP tanks is significantly lower compared to other materials, making them a sustainable choice for water storage.

In contrast, Steel Tanks have a high carbon footprint due to the energy-intensive manufacturing process and the raw materials required. Plastic Tanks pose a significant environmental concern as they contribute to microplastic pollution, especially in disposal or degradation scenarios. Concrete Tanks, while durable, consume a large amount of natural resources during production, and their large weight makes transportation more energy-consuming. Additionally, concrete tanks are difficult to recycle, contributing to long-term environmental waste. Therefore, GRP tanks stand out as the most eco-friendly option for water storage, aligning with sustainability goals.

Scalability and Flexibility

One of the key advantages of GRP tanks is their modular design, which provides significant scalability and flexibility. These tanks can be easily expanded, relocated, or customized to meet changing water storage needs, making them ideal for projects that require growth or adjustments over time. Their flexibility in design and installation ensures that they can be adapted to various applications, from residential to large industrial projects.

In comparison, Steel Tanks are difficult and expensive to modify once installed, often requiring significant effort and cost for adjustments or expansions. Plastic Tanks offer limited flexibility in terms of size and capacity, making them less ideal for large-scale or evolving storage needs. Concrete Tanks, being permanent structures, cannot be easily scaled or relocated, making them unsuitable for applications where future growth or adjustments are anticipated. This makes GRP tanks the most adaptable and cost-effective option for long-term water storage solutions.

Real-World Case Studies

Municipal Water Storage: In a major city, the decision to choose a GRP tank for municipal water storage resulted in a savings of $2.6 million over a span of 50 years. While the initial investment was higher compared to other materials, the long-term benefits far outweighed the upfront cost. GRP’s durability, minimal maintenance, and longer lifespan contributed to significant savings in operational costs, including repairs, replacements, and treatment.

Industrial Water Storage: A large manufacturing facility opted for a GRP tank, leading to savings of $430,000 over time. The lower long-term maintenance and replacement costs associated with GRP tanks made them a far more economical choice than alternatives. The durability of GRP reduced the need for frequent inspections and repairs, which ultimately led to substantial cost reductions for the facility, proving that investing in GRP tanks can be a highly cost-effective solution for industrial water storage needs.

Conclusion

GRP panel water tanks offer significant long-term savings, thanks to their exceptional durability, minimal maintenance requirements, and energy-efficient design. When evaluating the total cost of ownership—which includes not only the initial investment but also operational, maintenance, and environmental costs—GRP tanks consistently emerge as the most cost-effective solution. Compared to steel, plastic, and concrete tanks, GRP tanks provide superior performance, lower long-term operational costs, and a reduced environmental impact, making them an ideal choice for a wide range of water storage applications. Contact Solico Tanks for all your water storage needs!