Introduction

Glass Reinforced Plastic (GRP) panel water tanks have become a leading solution for water storage in a variety of environments, thanks to their durability, versatility, and long-lasting performance. Ideal for both residential and industrial applications, these tanks offer exceptional structural strength while maintaining lightweight and modular flexibility. This detailed guide explores the key elements that make GRP panel tanks the preferred choice for reliable water storage across different sectors.

The Core Material: GRP Panels

At the heart of every GRP panel tank are the GRP panels themselves, which combine advanced manufacturing techniques and materials to deliver both strength and flexibility. GRP panels are constructed using Sheet Molding Compound (SMC) technology, which involves combining glass fibers, polyester resin, and various fillers under high pressure and heat. The resulting composite material offers robust strength with a lighter weight compared to other tank materials, making it ideal for large-scale water storage.

The glass fibers embedded in the polyester resin matrix provide these panels with excellent mechanical properties, allowing them to resist significant water pressure, environmental stresses, and physical impacts. This makes GRP tanks suitable for harsh environments such as high-moisture or extreme temperature regions, where tanks must endure ongoing strain without compromising performance. Furthermore, the panels’ resistance to corrosion ensures they maintain their integrity even in coastal or chemically hazardous settings, where conventional materials may degrade.

Another crucial feature of GRP panels is their smooth, non-porous surface, which helps prevent bacterial, algae, and mold growth within the tank. This ensures that water stored in GRP tanks remains clean and safe for both potable and non-potable uses. The smooth finish also allows for easy cleaning and maintenance, keeping the water quality high throughout the tank’s lifespan. GRP panels are available in multiple sizes and can be configured to meet various capacity requirements, offering a highly customizable solution for any water storage need.

Strength and Durability: The Role of Fasteners

To assemble a GRP panel water tank into a secure, leak-proof structure, durable fasteners such as stainless steel bolts, nuts, and washers are used. These fasteners are integral to ensuring the tank remains strong and water-tight under the internal pressures exerted by the stored water. Stainless steel, particularly grades 316 and 304, is often selected for its resistance to corrosion, ensuring that the fasteners can withstand environmental factors like high humidity, saltwater, and industrial chemicals.

Proper installation of these fasteners is critical for maintaining the structural integrity of the tank. The fasteners need to be tightly secured to prevent water from leaking between the panels while ensuring that the tank remains intact under varying pressure and environmental conditions. The use of high-quality, corrosion-resistant fasteners enhances the overall longevity of the water tank, ensuring it remains functional and durable throughout its service life.

Ensuring a Leak-Proof Seal: Sealants and Gaskets

For GRP water tanks to perform effectively over the long term, ensuring a secure, leak-free seal between the panels is essential. This is achieved through the use of sealants and gaskets, which are applied between the panel edges to prevent water leakage. Non-toxic rubber foam is the most commonly used sealant in these applications, as it offers excellent adhesion and remains flexible over time, even in varying temperatures. Its durability ensures that the seal remains intact, preventing leaks despite the expansion and contraction of the tank due to temperature fluctuations.

In addition to rubber foam, materials like silicone and polyurethane are also employed in specific tank designs, offering superior flexibility, thermal resistance, and longevity. Silicone is ideal for extreme temperatures, while polyurethane is known for its durability and water resistance. Gaskets, made from rubber or silicone, are placed between the flanges of the panels to ensure an airtight seal. These gaskets prevent water from leaking at the panel junctions and contribute to the tank’s overall performance.

Structural Reinforcement: Support Systems

Support structures are necessary to enhance the strength and stability of GRP water tanks, particularly as they increase in size. External reinforcements, such as box sections and angles, help prevent the tank walls from bulging under the weight of the water. These reinforcements are crucial for maintaining the tank’s shape, especially under the hydrostatic pressure exerted by the water inside. Internal reinforcements, such as tie rods and bracing systems, are used to evenly distribute the weight of the water and reduce internal stress, ensuring the tank remains stable and secure.

Both external and internal supports are made from corrosion-resistant materials such as hot-dipped galvanized steel or stainless steel. These materials are chosen for their ability to resist degradation in challenging environments, ensuring that the tank remains strong and functional even in areas subject to extreme weather, seismic activity, or industrial conditions.

Base Support: A Foundation for Stability

The base of the tank is essential for its long-term stability. Whether it’s a concrete foundation or a pier wall, the base ensures that the tank remains level and structurally sound. A stable base also helps evenly distribute the weight of the tank and the water, preventing any shifting or settling that could compromise the tank’s integrity over time. The base design is particularly important for large-scale tanks and those located in areas with uneven terrain or high water tables.

In many cases, a pier wall foundation is used for externally flanged tanks, as it provides additional stability and prevents the accumulation of stagnant water. For internally flanged and internally built tanks, concrete foundations offer a solid base that can handle the heavy load of water. Both foundation types require careful consideration of environmental factors, such as soil conditions, water table levels, and potential external stresses, to ensure that the tank remains securely anchored.

Accessories for Enhanced Functionality

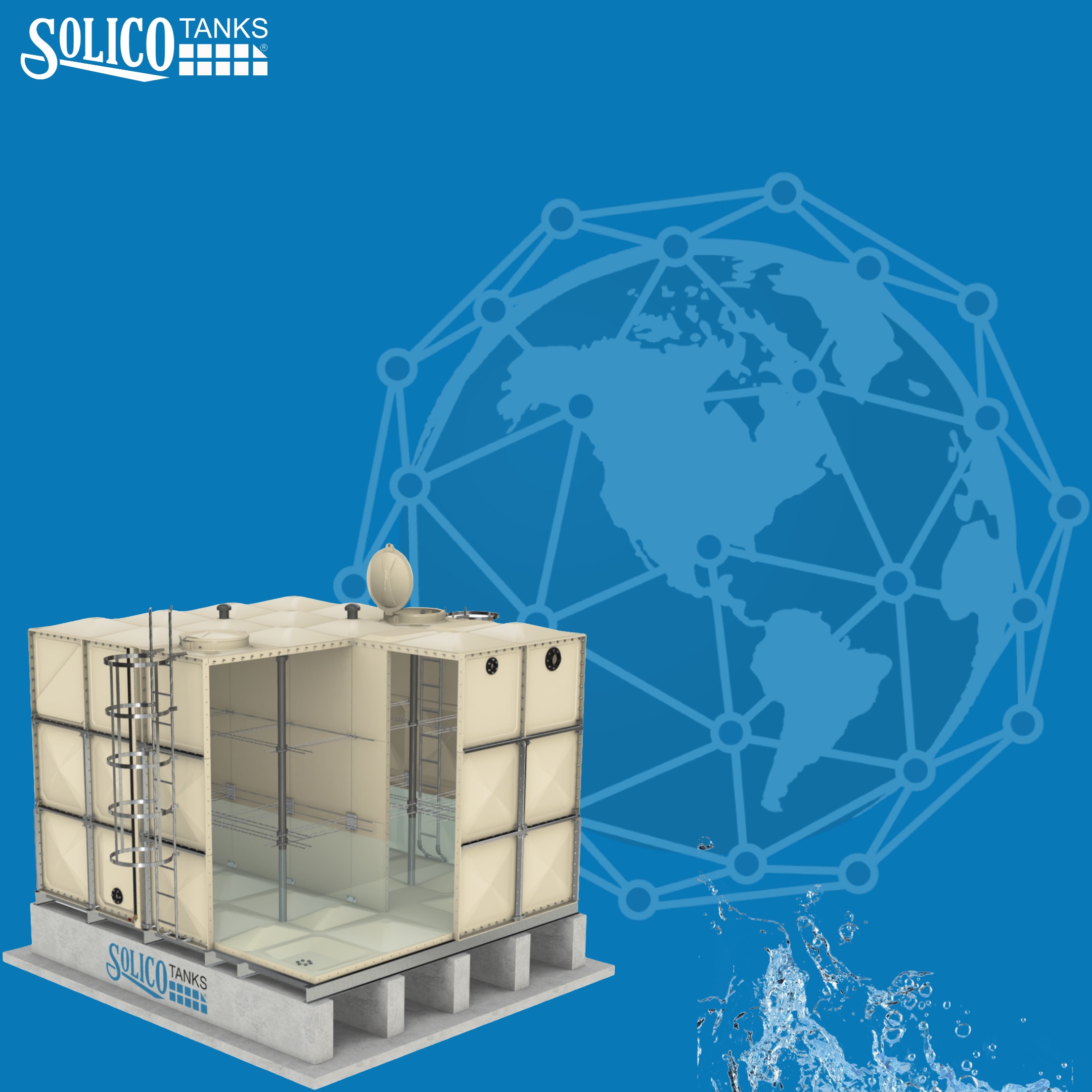

To improve the usability and efficiency of GRP water tanks, various accessories are incorporated. These accessories include inlet and outlet connections, overflow screens, manhole covers, ladders, and access points. Inlet and outlet connections allow for seamless integration with water supply systems, ensuring that the tank fills and empties at the required rates without compromising pressure or functionality. Overflow screens help filter out debris and prevent contamination, while manhole covers provide easy access for maintenance and inspections.

Ladders and safety rails are essential for providing secure entry and exit during maintenance, ensuring worker safety and compliance with regulations. These accessories enhance the functionality and reliability of GRP tanks, making it easier to maintain the tank’s performance and extend its lifespan.

Thermal Insulation: Protecting Water Quality

Many GRP water tanks are equipped with thermal insulation, such as expanded polystyrene (EPS), to help regulate the water temperature and preserve its quality. Insulation helps maintain a stable water temperature, preventing conditions that could lead to bacterial or mold growth. EPS insulation is particularly effective in high-temperature environments, as it prevents heat buildup and keeps the water cool. This ensures that water remains safe and hygienic, especially for potable uses.

Conclusion

GRP panel water tanks are an outstanding solution for water storage needs, offering durability, flexibility, and long-term reliability. Their lightweight yet strong design, combined with advanced materials and engineering, makes them ideal for a variety of applications. Whether for residential, commercial, or industrial use, GRP water tanks provide an efficient, secure, and cost-effective way to store water while ensuring that it remains safe and clean for years to come. With careful consideration of the materials, components, and support systems, these tanks can provide exceptional service even in the most demanding environments. Contact Solico Tanks for all your water storage needs!